PERSEUSTM

Detect compressed air leaks in real-time and

benefit from massively scalable energy savings

Our newest offering, PERSEUS, allows industrial manufacturers to carefully manage and monitor the use of compressed air – the most expensive source of energy in a plant. PERSEUS can reduce compressed air requirements by 20-30% resulting in corresponding energy savings.

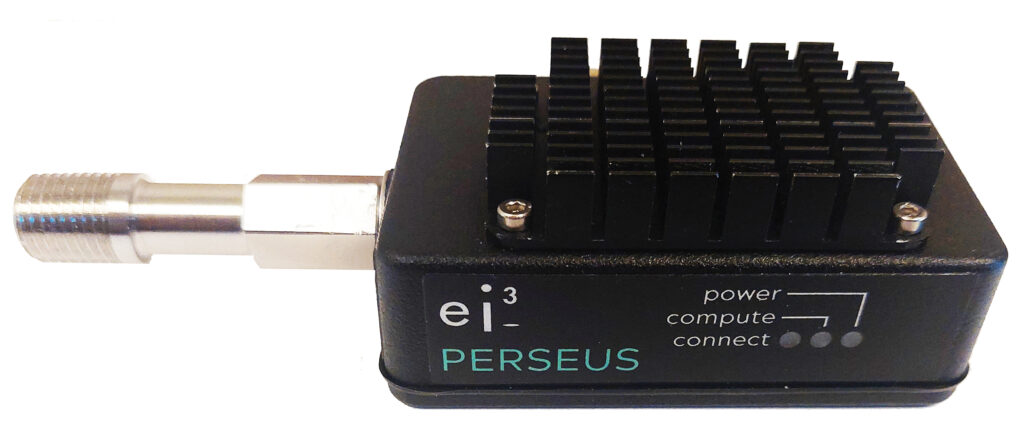

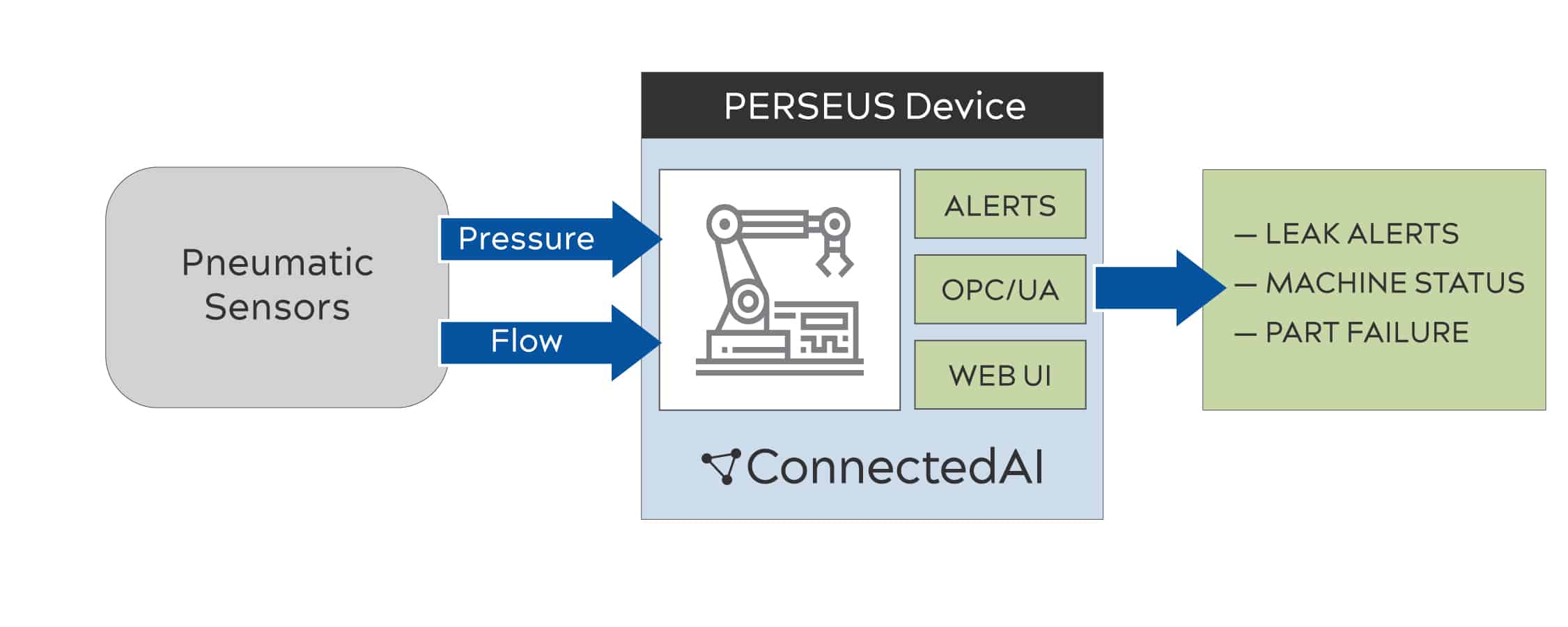

PERSEUS is a hardware solution with an accompanying IIoT application:

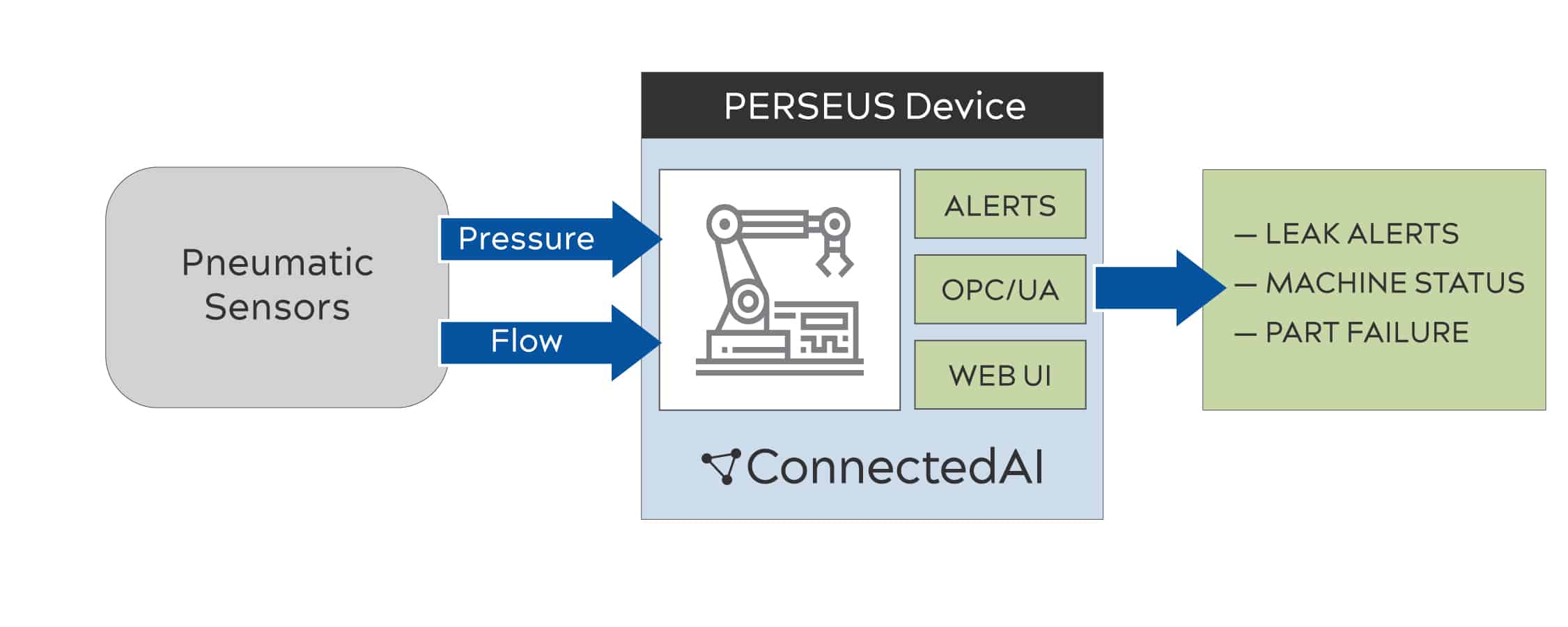

- PERSEUS functions as an automatic, continuous, customized leak detection edge device that applies advanced analytics to air flow and pressure data.

- Uses ConnectedAI to learn regular operating patterns and detect problems as they occur, dispatching timely alerts to relevant parties for further action.

The ei3 Advantage

Real-Time, Continuous Detection

Clients can do away with reactive fixes and get alerts in real-time. Instrumental in implementing a preventative leak-fix program.

Long-term data storage

Stores a local on-board history of all relevant machine data for analysis and long-term trending, with data storage for up to 30 years.

Synergistic

Can provide superior detection and remediation when used in tandem with on-site, portable devices like the Ultrasonic Detector.

Enhanced Accuracy

PERSEUS uses advanced algorithms using artificial intelligence and machine learning to create highly accurate results.

SCALABLE

Can scale comfortably depending on your requirements and needs.

PLUG-AND-PLAY

Easy to set up.

Can compressed air leaks be detected and fixed with an ultrasonic detector or other methods?

Other methods do not allow continuous monitoring of a machine’s pneumatic flow and pressure data, and require skilled operators to scan all potential areas from time to time physically. Other traditional methods such as applying soapy water to affected areas with a paintbrush are messy and time-consuming.

Air consumption threshold alerts can be added to a machine control system. But to avoid sending out nuisance alerts the thresholds are usually set to very high levels – levels that will not capture much of the leak avoidance savings.

None of these methods come close to the ease and accuracy that PERSEUS can provide when detecting air leaks.

Insights are delivered using an on-board UI, Alerts, or via OPC/UA for plant integration

Our newest offering, PERSEUS, allows industrial manufacturers to carefully manage and monitor the use of compressed air – the most expensive source of energy in a plant. PERSEUS can reduce compressed air requirements by 20-30% resulting in corresponding energy savings.

PERSEUS is a hardware solution with an accompanying IIoT application:

- PERSEUS functions as an automatic, continuous, customized leak detection edge device that applies advanced analytics to air flow and pressure data.

- Uses ConnectedAI to learn regular operating patterns and detect problems as they occur, dispatching timely alerts to relevant parties for further action.

The ei3 Advantage

Real-Time, Continuous Detection

Clients can do away with reactive fixes and get alerts in real-time. Instrumental in implementing a preventative leak-fix program.

Long-term data storage

Stores a local on-board history of all relevant machine data for analysis and long-term trending, with data storage for up to 30 years.

Synergistic

Can provide superior detection and remediation when used in tandem with on-site, portable devices like the Ultrasonic Detector.

Enhanced Accuracy

PERSEUS uses advanced algorithms using artificial intelligence and machine learning to create highly accurate results.

SCALABLE

Can scale comfortably depending on your requirements and needs.

PLUG-AND-PLAY

Easy to set up.

Can compressed air leaks be detected and fixed with an ultrasonic detector or other methods?

Other methods do not allow continuous monitoring of a machine’s pneumatic flow and pressure data, and require skilled operators to scan all potential areas from time to time physically. Other traditional methods such as applying soapy water to affected areas with a paintbrush are messy and time-consuming.

Air consumption threshold alerts can be added to a machine control system. But to avoid sending out nuisance alerts the thresholds are usually set to very high levels – levels that will not capture much of the leak avoidance savings.

None of these methods come close to the ease and accuracy that PERSEUS can provide when detecting air leaks.

Insights are delivered using an on-board UI, Alerts, or via OPC/UA for plant integration

Can compressed air leaks be detected and fixed with an ultrasonic detector or other methods?

Other methods do not allow continuous monitoring of a machine’s pneumatic flow and pressure data, and require skilled operators to scan all potential areas from time to time physically. Other traditional methods such as applying soapy water to affected areas with a paintbrush are messy and time-consuming.

Air consumption threshold alerts can be added to a machine control system. But to avoid sending out nuisance alerts the thresholds are usually set to very high levels – levels that will not capture much of the leak avoidance savings.

None of these methods come close to the ease and accuracy that PERSEUS can provide when detecting air leaks.

The Overlooked Cost of Compressed Air Leaks

Commercial air compressors are a mainstay in many industrial facilities. These devices cost more to operate than to purchase, requiring substantial energy to run. All pneumatic systems experience some leakage, most of the time due to systemic issues, however anything beyond a reasonable level (such as a 20% +leak rate) would call for immediate maintenance attention. Compressor air leaks can result in:

- Direct Financial Losses: Every excess liter-per-minute of air produced due to leaks directly adds electricity costs. Typical compressors consume between 18-22 kW per 100 CFM. The Compressed Air and Natural Gas Institute (CAGI) reports that a SINGLE ¼-inch leak can cost about $2500-$8000 a year. These high costs are getting worse because electricity rates are going up for most manufacturers.

- Additional Infrastructural Costs: With increased air consumption due to leaks, facilities might invest in more infrastructure to meet the needs of their pneumatic equipment, resulting in poor ROI.

- Increased Downtime: For facilities relying heavily on compressed air systems, leaks can constantly subject infrastructure to a maintenance and repair cycle – adding to downtime. Compressors undergo more stress to compensate for losses, decreasing their lifecycle and efficiency.

- Productivity Impact: Pneumatic machines and tools with leaky systems receive inadequate compressed air and can be underpowered causing them to have longer or irregular cycle times, suffer from lower productivity and take longer to complete jobs.

- Direct Financial Losses: Every excess liter-per-minute of air produced due to leaks directly adds electricity costs. Typical compressors consume between 18-22 kW per 100 CFM. The Compressed Air and Natural Gas Institute (CAGI) reports that a SINGLE ¼-inch leak can cost about $2500-$8000 a year. These high costs are getting worse because electricity rates are going up for most manufacturers.

- Increased Downtime: For facilities relying heavily on compressed air systems, leaks can constantly subject infrastructure to a maintenance and repair cycle – adding to downtime. Compressors undergo more stress to compensate for losses, decreasing their lifecycle and efficiency.

- Productivity Impact: Pneumatic machines and tools with leaky systems receive inadequate compressed air and can be underpowered causing them to have longer or irregular cycle times, suffer from lower productivity and take longer to complete jobs.

- Additional Infrastructural Costs: With increased air consumption due to leaks, facilities might invest in more infrastructure to meet the needs of their pneumatic equipment, resulting in poor ROI.

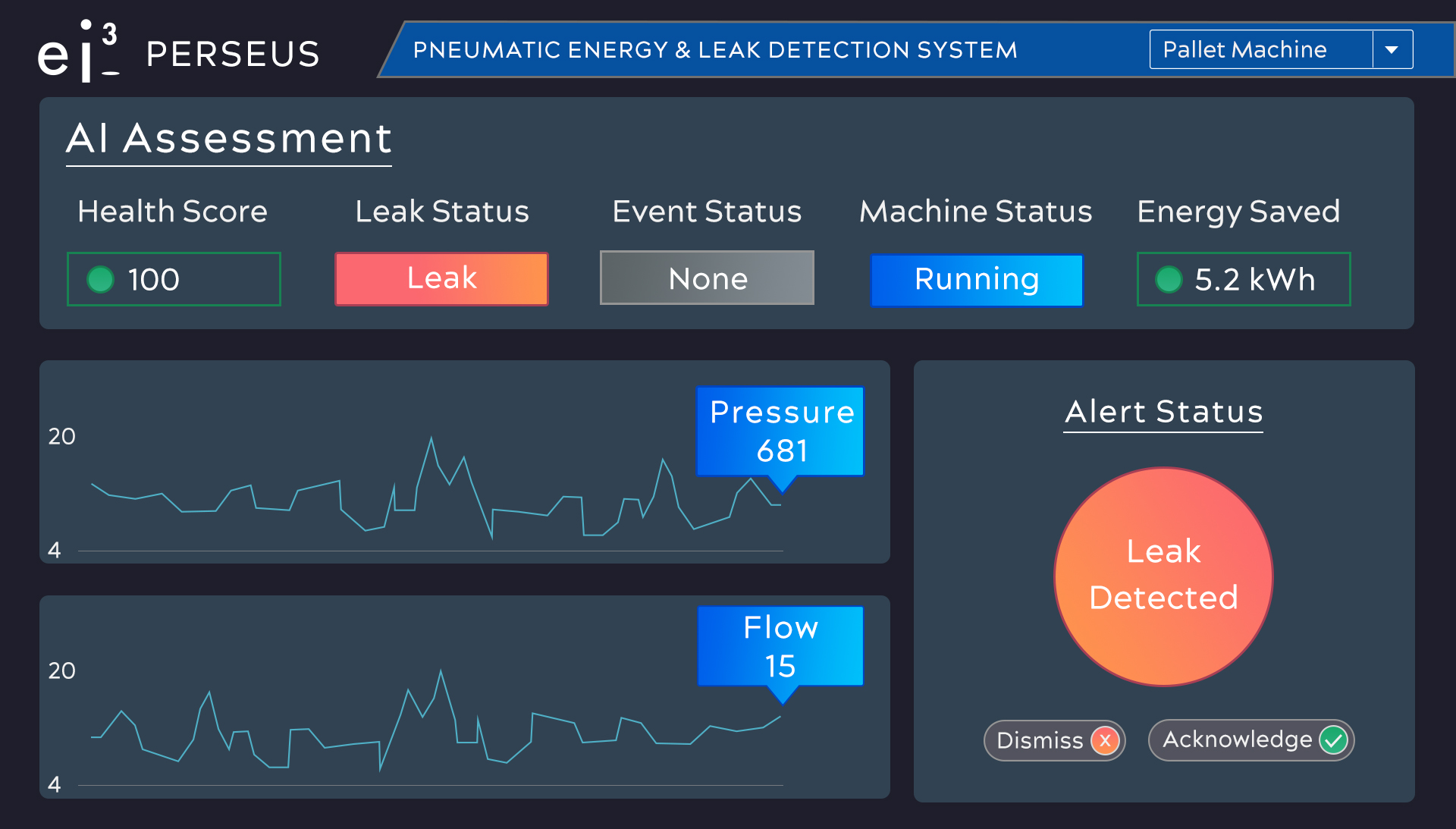

Monitor Compressed Air Usage Easily with User-Friendly Dashboards

ei3’s tailored dashboards are designed to present actionable insights derived from PERSEUS in a readily understandable format. This enables users to promptly and efficiently make informed decisions regarding a plant’s compressed air usage.

Navigate through essential compressed air usage metrics, including real-time data on leaks and machine status, energy savings, health scores, and receive preventative alerts—all to your preference.

Connecting the Shop Floor to PERSEUS

connect

ei3’s PERSEUS device works perfectly with modern pneumatic air management systems. PERSEUS connects to the pneumatic air supply system at the entry point to individual machines where it continuously monitors flow and pressure data.

Analyze & Alert

With its high-powered computational capabilities, PERSEUS learns normal machine operations and analyzes them for leak detection. When PERSEUS detects a leak, relevant personnel are notified, and alerts are dispatched to a variety of end-user devices.

Improve

Technicians can be dispatched to problem sites as soon as leaks are detected or through a predictive maintenance strategy based on trend and part status information provided by PERSEUS.

Download the Product Sheet