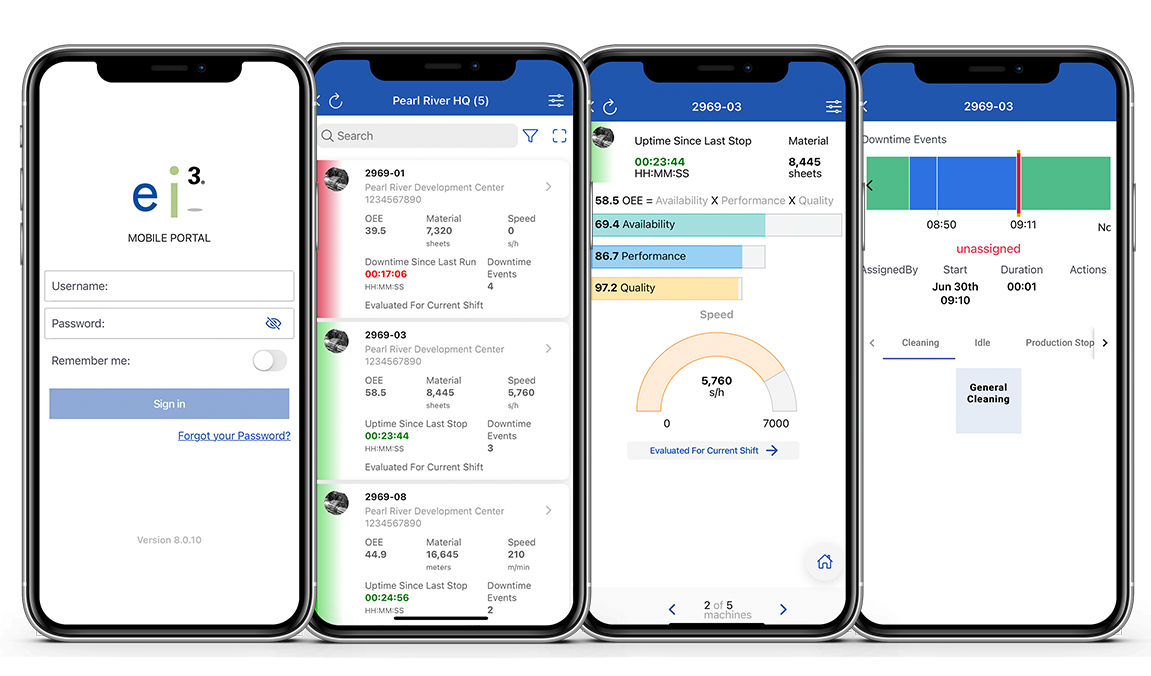

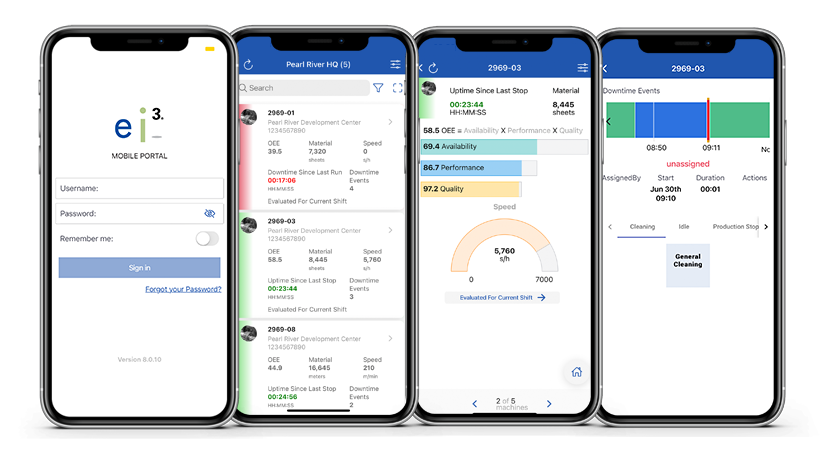

MOBILE APPLICATIONS

Access Factory Floor Productivity with Real-Time Equipment Status, Performance Trends, and Automatic Alerts from your Phone

With ei3 mobile AppS, users can gain valuable insights into their manufacturing processes, including:

- Access current OEE and a four-hour trend analysis.

- Retrieve information on the current shift, current job, or the past 24 hours of a specific machine.

- Evaluate and assign machine downtime, ensuring efficient production.

- Continuously monitor production quality and receive real-time reports.

- Gain insights into machine speed to optimize performance.

- Access specific maintenance information related to tools, parts, and assemblies.

- View historical maintenance records or perform remote maintenance when necessary.

With ei3 mobile AppS, users can gain valuable insights into their manufacturing processes, including:

- Access current OEE and a four-hour trend analysis.

- Retrieve information on the current shift, current job, or the past 24 hours of a specific machine.

- Evaluate and assign machine downtime, ensuring efficient production.

- Continuously monitor production quality and receive real-time reports.

- Gain insights into machine speed to optimize performance.

- Access specific maintenance information related to tools, parts, and assemblies.

- View historical maintenance records or perform remote maintenance when necessary.

Stay Connected with Your Machines

Stay Connected with Your Machines

ei3’s mobile applications enable plant personnel to effortlessly monitor their machines. Customizing displays with preferred data metrics and machines allows for efficient tracking of machine performance, whether chosen based on urgency, personal preference, or expertise. Our mobile apps serves as a pivotal first step for quick and comprehensive machine assessment and troubleshooting. Our range of online applications offer more extensive and detailed data-analysis and problem resolution across various aspects of the production process.

ei3 mobile applications enable plant personnel to effortlessly monitor their machines from their phones. Customizing displays with preferred data metrics and machines allows for efficient tracking of machine performance, whether chosen based on urgency, personal preference, or expertise. Our mobile apps serves as a pivotal first step for quick and comprehensive machine assessment. Our range of online applications offer more extensive and detailed data-analysis and problem resolution across various aspects of the production process.

The ei3 Advantage

KPI’s IN Real-Time

Visualize & verify machine performance indicators with a simple click.

PREDICTIVE MAINTENANCE

Proactively address machine performance with accurate predictive insights for parts and tools.

CUSTOMIZABLE DISPLAYS

Tailor your display to track the specific machines and data insights you require.

Auto-Alert Enabled

Set-up custom alerts to notify yourself or your teams of events that need attention via Email, SMS or pager.

DOWNTIME ASSESSMENT

Identify and troubleshoot downtime, reducing costs and increasing operational efficiency.

WHITE-LABEL SOLUTION

Incorporate your brand logo and identity into our ready-to-deploy solution, creating a personalized app for your customers.

The ei3 Advantage

KPI’s IN Real-Time

Visualize & verify machine performance indicators with a simple click.

PREDICTIVE MAINTENANCE

Proactively address machine performance with accurate predictive insights for parts and tools.

CUSTOMIZABLE DISPLAYS

Tailor your display to track the specific machines and data insights you require.

Auto-Alert Enabled

Set-up custom alerts to notify yourself or your teams of events that need attention via Email, SMS or pager.

DOWNTIME ASSESSMENT

Identify and troubleshoot downtime, reducing costs and increasing operational efficiency.

WHITE-LABEL SOLUTION

Incorporate your brand logo and identity into our ready-to-deploy solution, creating a personalized app for your customers.

Connecting ei3 Mobile Apps to the Shop Floor

STEP 1. CONNECT

Our edge device, the Amphion, connects to your equipment’s PLC or database. Once plugged into the machine’s control cabinet, the Amphion will interrogate the machine controllers 24×7, accurately detecting and recording downtime events.

STEP 2. MEASURE

Collect and analyze downtime/uptime, production quality, and lifecycle data. This allows our mobile application to deliver key performance indicators in real-time.

STEP 3. IMPROVE

With this information your team addresses any potential or ongoing issues seamlessly.