The Challenge

NYX, like many American manufacturers, is experiencing a range of business challenges: finding staff, rising costs, growing customer demands (pricing, delivery times, product quality, etc.), and increasing sustainability requirements, to name just a few. Traditional solutions to these challenges are no longer able to keep up. Hiring more operators (oftentimes novices), buying replacement machinery, or increasing planned downtime (to increase machine reliability) is uneconomical and comes with serious efficiency costs. Manual downtime recording and quality testing are error-prone, subject to human interpretation (albeit often benevolent), and conceal the true causes of problems, while preventative maintenance and rapid repair solutions merely offer clumsy solutions to the visible effects of underlying issues.

About NYX

NYX is a leading automotive manufacturer and heavy user of Milacron’s large-scale injection molding machines. NYX signed up to Milacron’s “M-Powered” service. M-Powered comprises a portfolio of analytical and observational IIoT-based technologies, developed by ei3, which enables Milacron’s clients such as NYX to monitor and continuously optimize their manufacturing processes.

The Solution

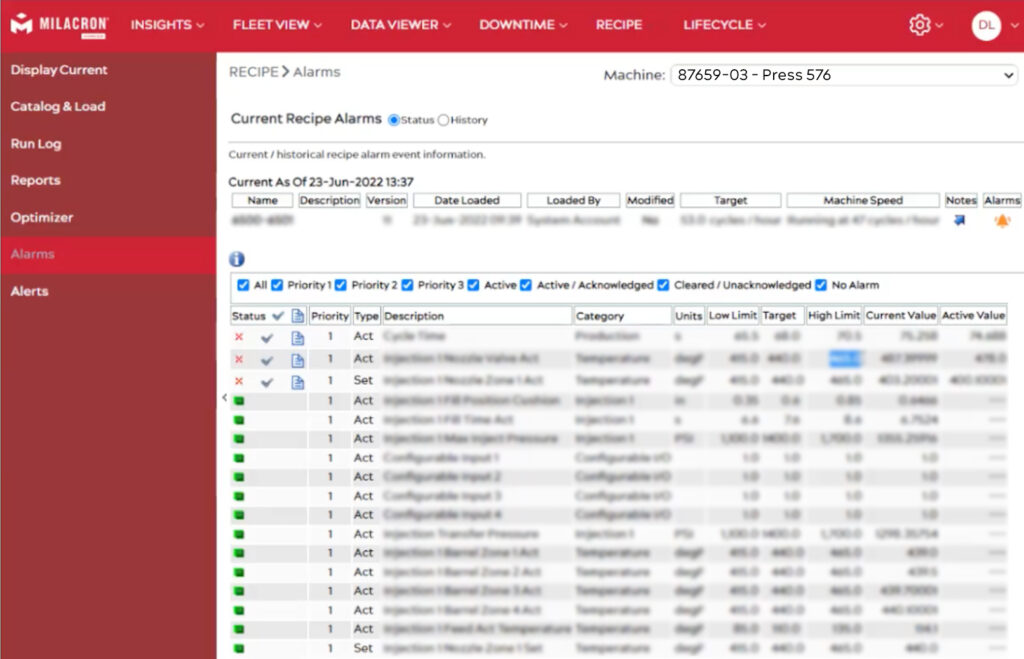

IIoT-based solutions, such as Milacron’s M-Powered developed by ei3, address NYX’s manufacturing challenges directly. Quality testing is conducted with greater precision through the online collection of test results, with real-time data analysis to account for irregularities and inaccuracies in the testing process. The results are scrutinized for trends and patterns related to machine function. The “M-Powered” recipe management tools proactively alert operators to address irregularities highlighted in the test data before they escalate into significant quality issues.

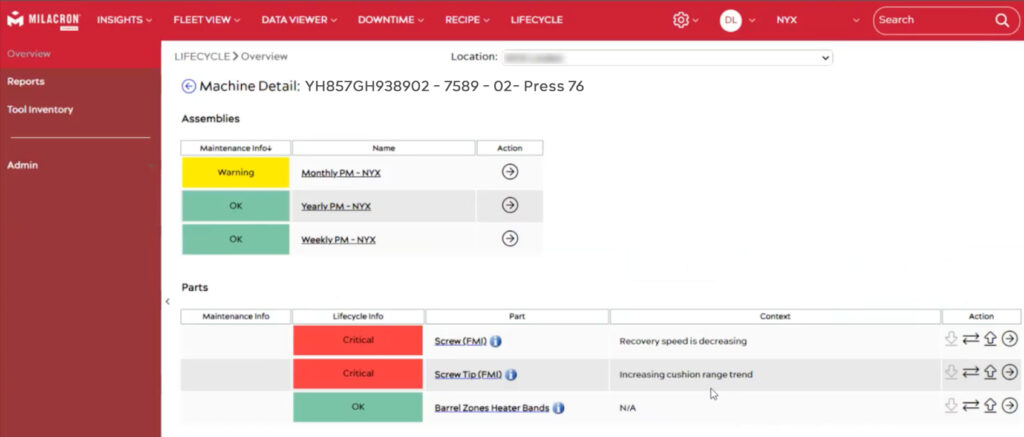

In numerous instances, ei3’s AI-driven cause-effect pattern identification process provides valuable insights to operators, facilitating the identification of the root causes of downtime. Unusual events are automatically identified and compared with baseline machine scores, linking problems directly to specific components or operator processes. NYX utilizes the informative graphing functions within “M-Powered” to emphasize key downtime areas, allowing operators to swiftly extract significant insights. They can pinpoint the relevance of changeover times, repair times, start-up times, or machine parts prone to failures.

Results

23% Reduction in Scrap Rates

Fewer than one part in 100 deviating from stringent quality standards.

10% Reduction in Unplanned Machine Downtime

Pivotal role in monitoring wear and tear, enabling timely replacement of critical components, preventing noticeable declines in quality and performance.

8-12% Reduction in Routine Maintenance Expenditures

Intelligent calculator leveraging real-time machine data for optimal maintenance windows, decreasing resources required for routine activities.

Operational Efficiency Transition

Complete abandonment of paper tracking for process verification, two-hour inspections, and maintenance documentation.

Recipe Management Success

Crafting functional recipes for consistent, high-quality production without additional expenses on quality-control personnel.

Quality Management Efficiency

Valuable insights provided to quality operators through dashboards and automated text alerts.

Hear from the NYX team

One thing that we have gained from this system is a dashboard developed that is very visual-control. If a process is running out of what tolerances are set or what our desired process is, it will flash yellow so we know instantly what’s going on.

Data analysis from the technology is endless. You can go back and see every parameter or setup for any part you produce at any time....With everything having extended lead time recently, double or triple what they were a couple of years ago, it’s good to be able to monitor the equipment and predict potential failure to allow us to reach to those in advance. It really helps to minimize the possibility of unplanned downtime due to inability to get spare parts in a timely manner.