The Challenge

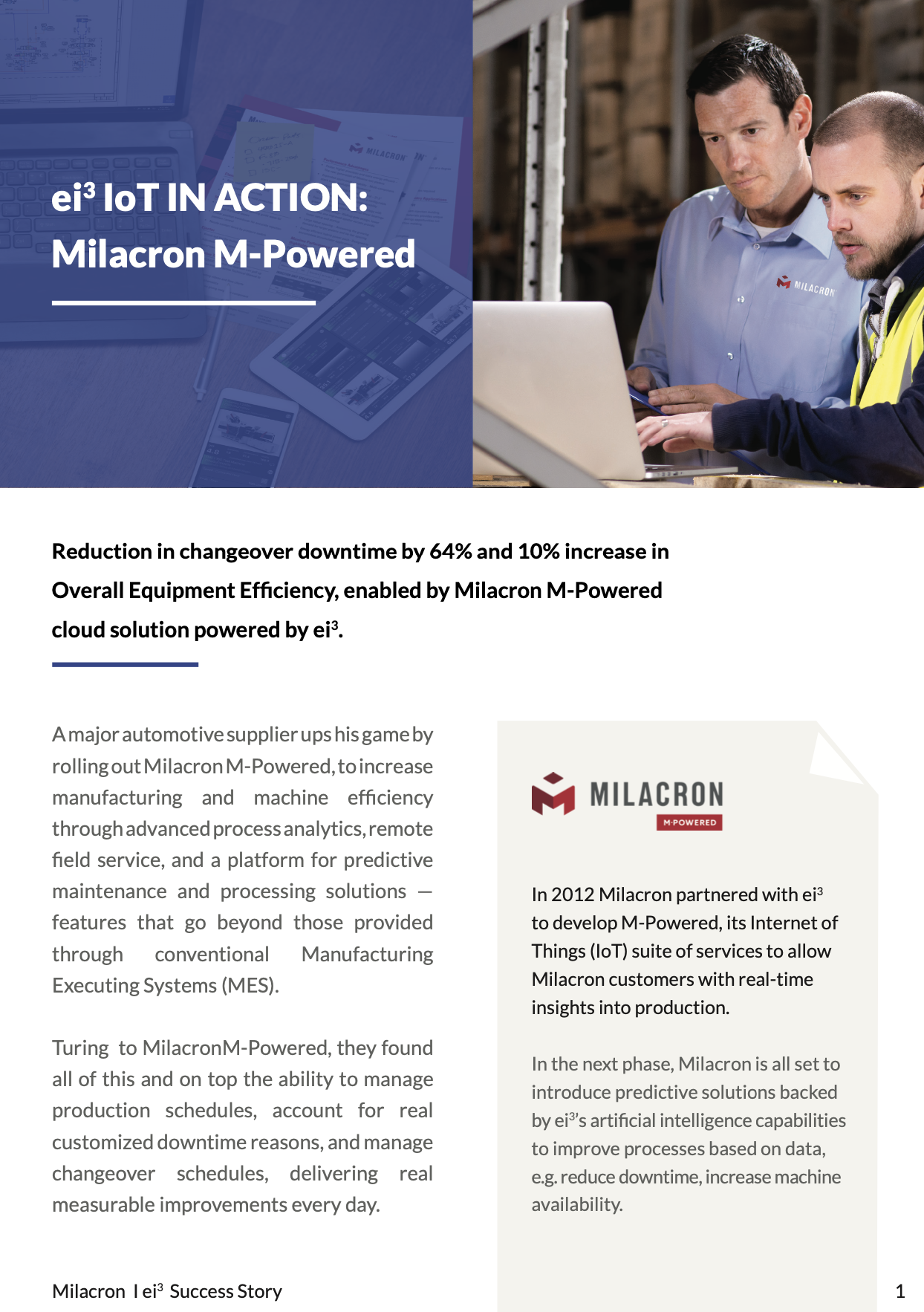

A major automotive supplier faced the challenge of high changeover downtime, impacting Overall Equipment Efficiency (OEE). The need to enhance manufacturing efficiency and address downtime issues prompted them to seek innovative solutions.

The Solution: ei3-Backed Excellence in Milacron M-Powered

The automotive supplier adopted Milacron M-Powered, leveraging advanced process analytics, remote field service capabilities, and a predictive maintenance platform to enhance its manufacturing processes. This cloud solution, powered by ei3, surpassed conventional Manufacturing Executing Systems (MES) by offering a comprehensive suite of features.

IMPLEMENTATION

- Advanced Analytics and Remote Service: Milacron M-Powered facilitated real-time insights into production, enabling the management of production schedules, customized downtime reasons, and changeover schedules.

- Enhanced Team Coordination: Real-time information on jobs, machine states, and schedules improved team coordination, leading to an overall reduction in downtime for the automotive manufacturer.

- Daily Reporting for Productivity: Milacron’s M-Powered Service Portal provided daily reports to team leads, demonstrating increased productivity, improved speed, quality, and enhanced customer satisfaction.

Results

64% Reduction in Changeover Downtime

Over a 20-month period, Milacron M-Powered successfully achieved a 64% reduction in changeover downtime for the automotive manufacturer by focusing on machine improvements and addressing unassigned and scheduled downtime instances.

10% increase in Overall Equipment Efficiency

Read the case study for details on achieving reduced changeover downtime