The Challenge

In pursuit of a groundbreaking solution, the company, with its rich history of innovation, sought to revolutionize the manufacturing sector. Their objective was clear: to enhance value for their customers by addressing challenges prevalent in the industry. Aiming for a comprehensive remedy, they envisioned a system that not only eliminated machine downtime but also addressed operator concerns, providing a reliable framework for improved operations.

KEY CHALLENGES FACED:

- Monitoring operational data seamlessly from machines to the entire plant and presenting it meaningfully.

- Establishing uniform metrics across diverse machines from various manufacturers and time periods.

- Facilitating data-driven decisions at both top-level management and on the factory floor.

- Optimizing machine recipes and enhancing quality control.

- Identifying improvement opportunities while establishing fail-safes against previously undetectable problems.

These challenges, intricately linked, necessitated a holistic and integrative approach. The company found the perfect solution in the complete suite of ei3’s ConnectedAI offering, encompassing advanced AI algorithms for packaging efficiency.

About the Manufacturer

In 2012, a prominent North American packaging company ventured into the realm of AI-powered, data-driven manufacturing by incorporating ei3 technology into a single laminator.

Now, with 70 machines across five locations connected to ei3’s solution, the company has wholeheartedly embraced data-driven machine operations. Beyond mere metrics, the company experiences reduced downtime, improved quality control, and elevated customer satisfaction and loyalty.

The Solution

The company’s introduction to ei3 and its transformative capabilities began with the installation of a laminator from a prominent printing and converting machine builder. This leading manufacturer incorporates ei3’s secure IoT apps into all new equipment, allowing real-time data collection during production. Recognizing the significance of these capabilities in an industry with narrow profit margins, the company decided to extend ei3’s ConnectedAI solution beyond the laminator. The solution was retrofitted to older machines such as slitters, bag machines, and printing presses.

The implementation involves continuous 24/7 monitoring of data from all machines using ei3’s Amphion™ edge gateways, creating secure connections to various equipment. The collected machine data is centralized within ei3’s private cloud, where KPIs are computed, and ConnectedAI’s AI-based data science tools generate insights. These insights, accessible through various devices, from smartphones to HMI dashboards, are disseminated throughout the organization, supporting operators, quality control personnel, and management alike. With the integration of ei3’s suite of no-code IoT and AI apps—MONITOR, DOWNTIME, RECIPE, and QUALITY—applied to over 70 machines, the company establishes a robust foundation for data-driven decision-making and continuous improvement in packaging manufacturing.

Results

Maximized Machine Productivity

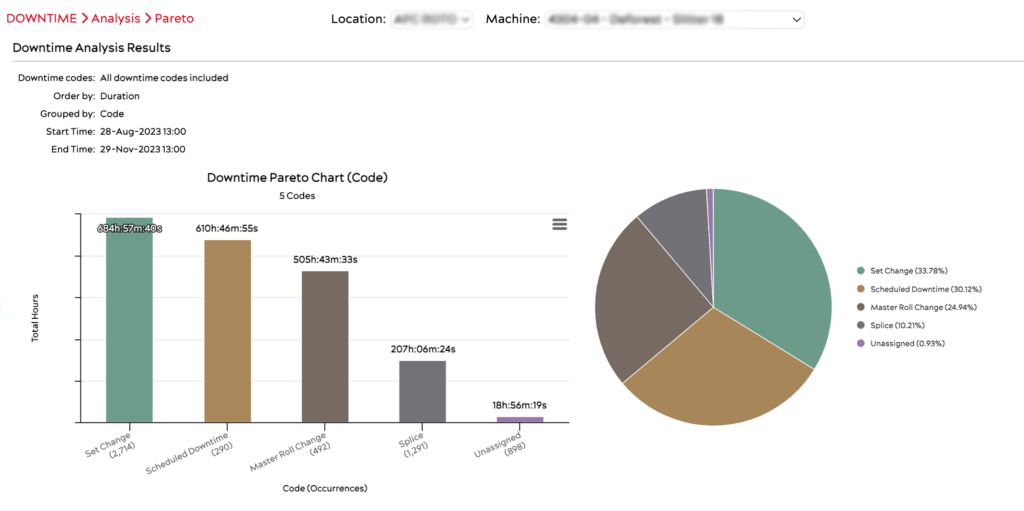

- Utilizes data from machine controllers to identify prominent causes of downtime.

- Employs analytics tools for continuous improvement projects.

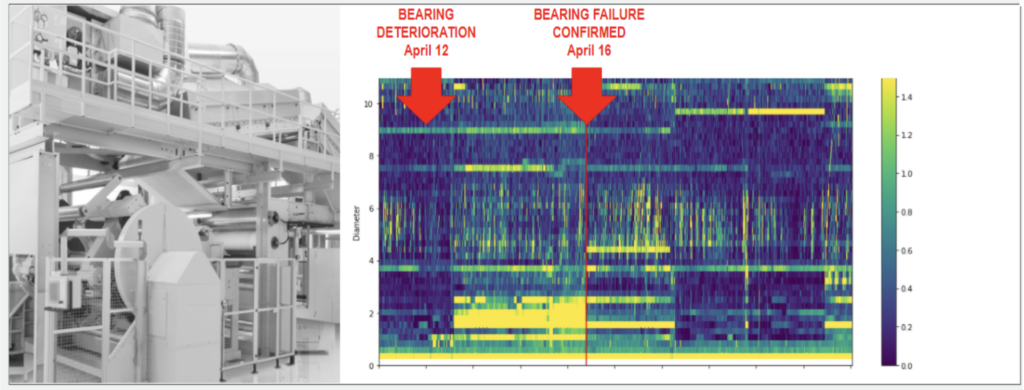

- Detected vibrations in a laminator before bearing failure, preventing production quality issues.

- Maximized machine productivity by addressing root causes of downtime.

Operational Efficiency Boost

- Efficiently manages machines across diverse lines and locations.

- Provides comprehensive insights on machine speed, material usage, OEE breakdown, and downtime.

- Significantly reduces downtime, enhancing overall operational efficiency.

Streamlined Machine Configuration

- Allows supervisors and operators to set ideal parameters based on previous data and experience.

- Creates a library of “good” settings for efficient adaptation of new machines to the overall production flow.

- Streamlines the configuration of new machines for changing client demands.

Consistent High-Quality Deliverables

- Facilitates real-time testing on various machines.

- Enables operators and QA techs to create testing sequences with customizable variables.

- Ensures consistent high-quality deliverables in the competitive packaging industry.

Discover how ei3's IoT solutions enhanced packaging productivity