The Challenge

Downtime poses a significant financial burden due to a combination of factors like labor costs, maintenance operations, and lost production. Traditionally, the only preventive measure was scheduled maintenance, which aimed to extend the life of machines and tools, minimizing unplanned downtime and performance degradation.

Seeking to drive competitive advantage while maintaining an emphasis on improving their carbon footprint, ORBIS partnered with Milacron and ei3 to adopt “M-Powered”, a suite of Industrial IoT and AI applications to help ORBIS optimize their machines, enhance the efficiency of reusable plastics manufacturing. This collaboration enabled ORBIS to enhance their machine functions, improve their service, and make significant progress towards their sustainability goals.

About ORBIS

ORBIS, a sister company of Menasha Corporation, has been a provider of innovative reusable plastic and steel packaging solutions since 1966. ORBIS caters to diverse markets, primarily focusing on retail supply, industrial, and automotive industries, delivering an extensive range of products from pallets and containers to totes and trays.

- Headquartered in Oconomowoc WI

- Over 2,600 employees and 55 locations throughout North America and Europe

The Solution

ORBIS leveraged M-Powered AI solutions to digitally monitor critical machine components’ health, such as heater bands, and proactively identify potential failures, optimizing reusable plastics manufacturing processes. The transition included converting maintenance dashboards into predictive alerts, akin to a car’s check engine light, detailing upcoming failures. This shift enabled ORBIS to replace components before failure, resulting in significant energy consumption savings and decreased cycle time. M-Powered’s predictive maintenance suite, with Application Programming Interfaces (APIs), facilitated automatic alerts, empowering ORBIS to take preventive actions swiftly.

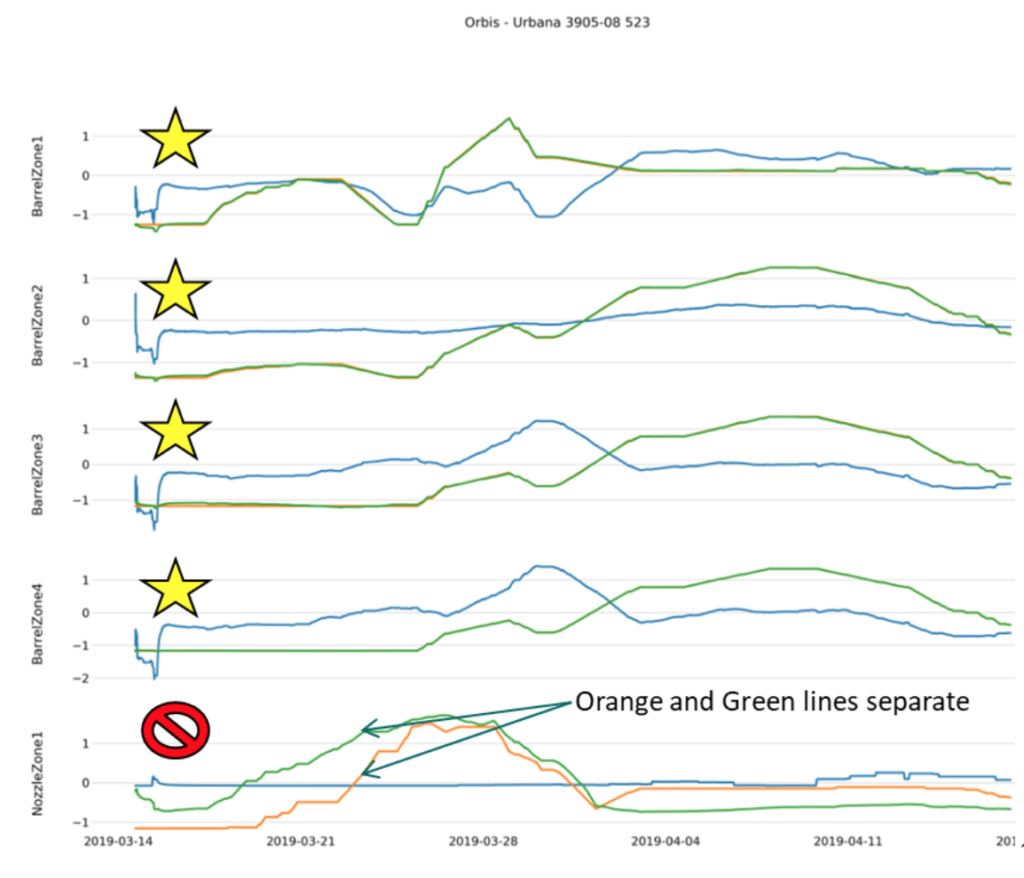

- Predicting Heater Band Failures:

- ei3’s continuous 24/7 data collection analyzed machine behavior and identified heater band failures.

- An algorithm was developed within three months, detecting potential failures by analyzing amperage and control signals.

- Proactive maintenance based on insights reduced unplanned downtime, saved costs, and increased productivity.

- In the first year with 22 connected machines, ORBIS eliminated over 7,000 hours of unplanned downtime and achieved a 1% reduction in scrap rate, improving product quality.

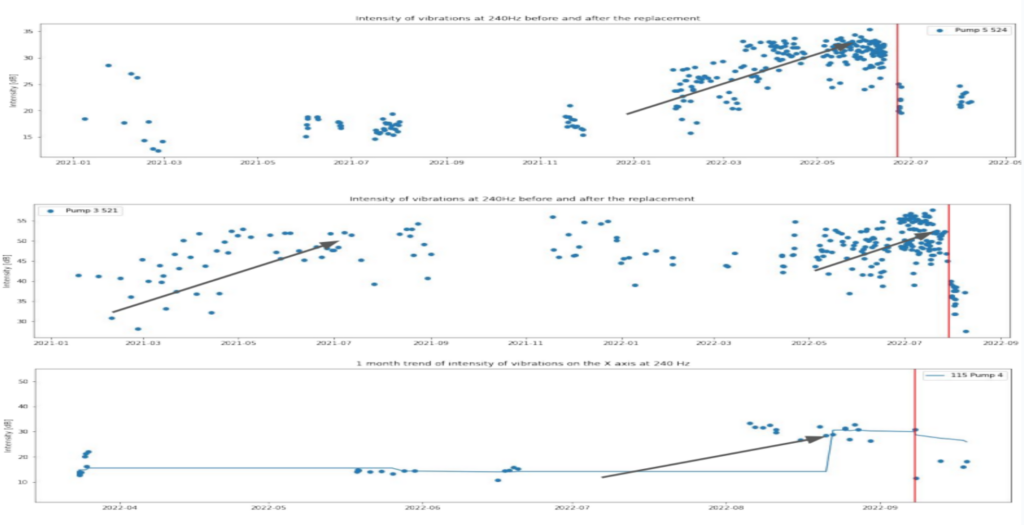

- Predictive Maintenance for Hydraulic Pumps:

- Symphony – the wave field sensor and ConnectedAI’s advanced AI algorithms monitored machine waves to predict hydraulic pump failures up to two months in advance.

- Deviations in pump health were detected, enabling proactive maintenance and preventing significant disruptions.

- Approximately 144 hours of unplanned downtime were prevented, leading to significant cost savings and improved efficiency

- Optimizing Feed Screw Settings:

- Multi-modal data analysis approach by ei3’s data scientists examined energy consumption for feed screws.

- Identified wear and tear effects on the plasticizing screw, providing advanced knowledge for timely replacements.

- Established optimal plasticizing screw tuning velocity, resulting in increased production, improved efficiency, and sustainability gains.

- Contributed to ORBIS’ sustainability posture, with one machine saving over 18,000 kWh in a year.

Results

1000 kWh of Energy Savings

Demonstrated commitment to sustainability by saving over 1,000 kWh of energy per machine per day

7,000 hours Reduction

Achieved over 7,000 hours reduction in unplanned downtime within the first year.

Lowered Scrap Rate by 1%

Successfully lowered scrap rates by 1%, reflecting improved product quality.

“At this point, we trust the data. Most of us look at the dashboard and if it says “heater band 3 is going bad,” we just go replace that heater band. We don’t even come in and look at the data anymore, we’ve gotten to that level of maturity.”

“Everyone in the industry is striving for zero unplanned downtime and improving their machine. I’ve been in the plastics industry for 33 years, and this has always been a goal no matter who I’ve worked for or with… increase uptime and improve machinery reliability.”