Introducing iPID:

Cutting-Edge Technology for Industrial Machine Health Monitoring

ConnectedAI employs a unique technology to monitor the machine’s internal control logic to detect developing imbalances that are indicative of the effects of wear and tear or mechanical malfunctions. This unique algorithm represents the state-of-the art in science-based predictive maintenance, and we are proud that our data scientists have even been recognized by the IEEE for iPID.

Introducing iPID:

Cutting-Edge Technology for Industrial Machine Health Monitoring

ConnectedAI employs a unique technology to monitor the machine’s internal control logic to detect developing imbalances that are indicative of the effects of wear and tear or mechanical malfunctions. This unique algorithm represents the state-of-the-art in science-based predictive maintenance, and we are proud that our data scientists have even been recognized by the IEEE for iPID.

The innovation behind iPID

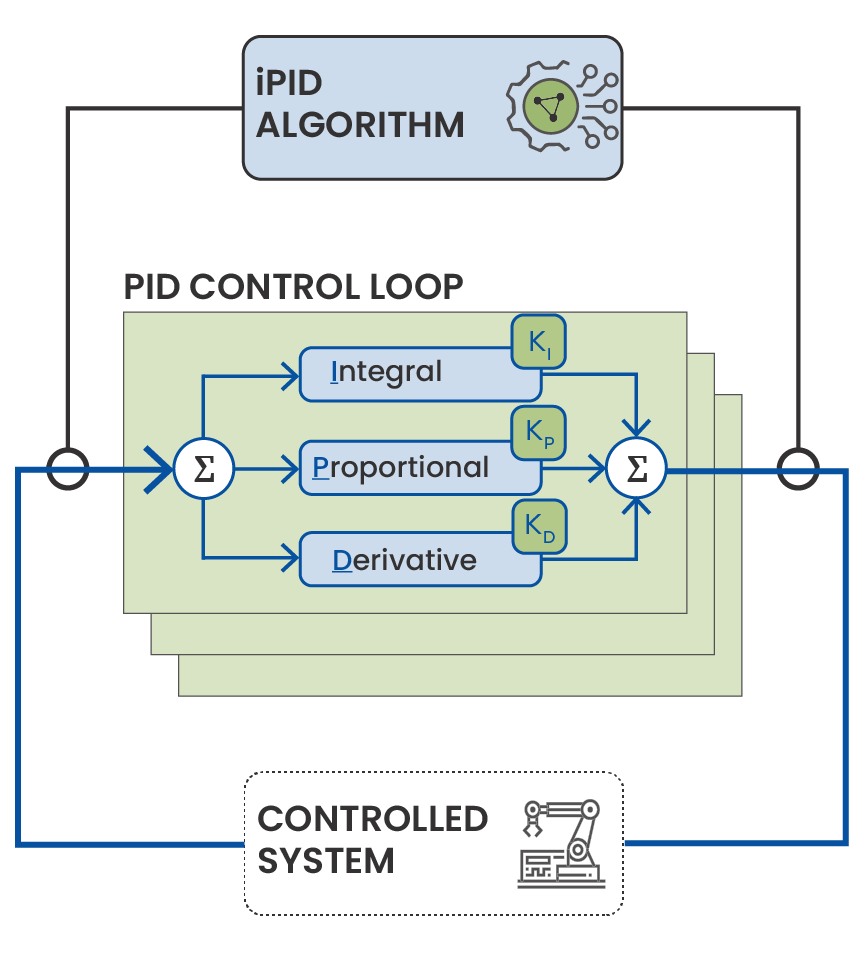

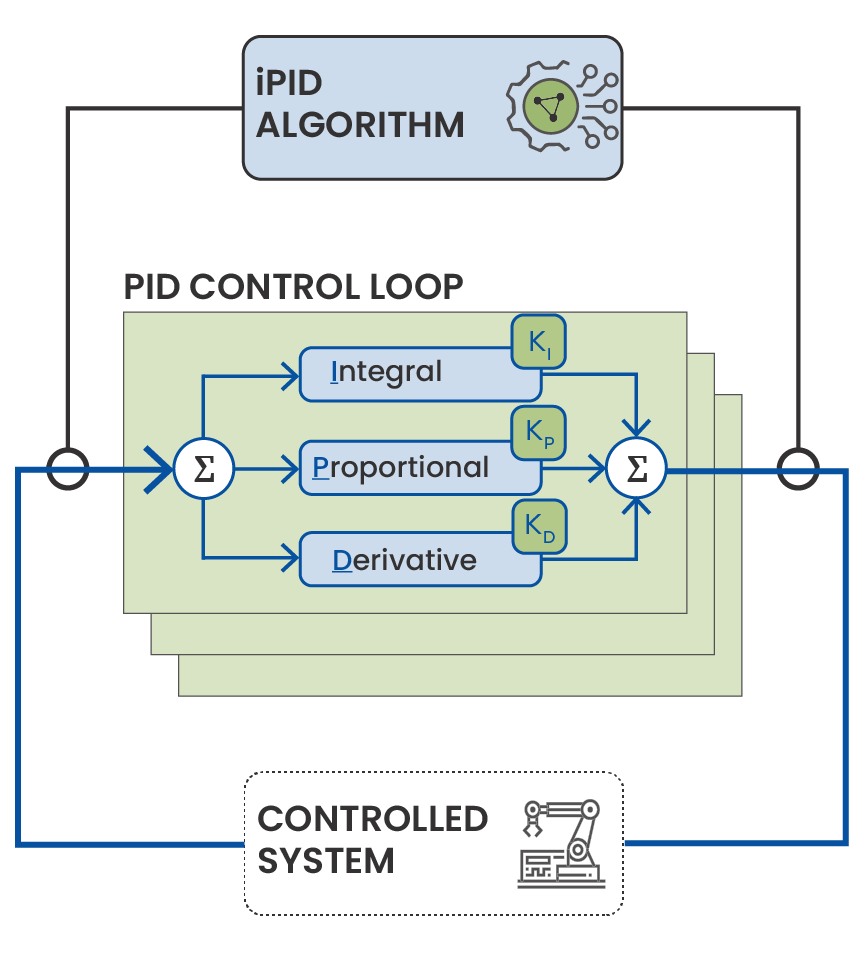

Our innovative solution: Inverse PID

Effective predictive maintenance solutions have traditionally required extensive implementation efforts to translate engineering knowledge into mathematical or algorithmic forms. This process is not only costly but often ultimately unsuccessful, as many machine failures are attributed to operator error rather than engineering flaws.

iPID stands apart by using a sound mathematical foundation to continuously monitor the machine’s existing digital control loops to identify and quantify the impact of wear and tear and mechanical anomalies. iPID operates without the need for additional sensors, making it a versatile and cost-effective solution for a wide range of industrial machines. By continuously monitoring the data already present in your digital controls, iPID can provide early warnings of malfunctions, allowing for timely intervention and maintenance.

The innovation behind iPID

Effective predictive maintenance solutions have traditionally required extensive implementation efforts to translate engineering knowledge into mathematical or algorithmic forms. This process is not only costly but often ultimately unsuccessful, as many machine failures are attributed to operator error rather than engineering flaws.

iPID stands apart by using a sound mathematical foundation to continuously monitor the machine’s existing digital control loops to identify and quantify the impact of wear and tear and mechanical anomalies. iPID operates without the need for additional sensors, making it a versatile and cost-effective solution for a wide range of industrial machines. By continuously monitoring the data already present in your digital controls, iPID can provide early warnings of malfunctions, allowing for timely intervention and maintenance.

Benefits of iPID

IPID provides high-traceability. Our method, grounded in mathematical principles, offers a clear and understandable pathway from data to diagnosis

BROAD

APPLICABILITY

Designed to work with a wide variety of industrial machines, regardless of their specific functions or configurations.

COST-

EFFECTIVE

Eliminates the need for additional sensors, reducing implementation costs.

EARLY

DETECTION

Identifies early signs of wear and tear or malfunctions, preventing unexpected downtime and costly repairs.

EASE OF

INTEGRATION

Operates on the data your digital controls already have, simplifying the integration process.

Benefits of iPID

IPID provides high-traceability. Our method, grounded in mathematical principles, offers a clear and understandable pathway from data to diagnosis

BROAD

APPLICABILITY

Designed to work with a wide variety of industrial machines, regardless of their specific functions or configurations.

COST-

EFFECTIVE

Eliminates the need for additional sensors, reducing implementation costs.

EARLY

DETECTION

Identifies early signs of wear and tear or malfunctions, preventing unexpected downtime and costly repairs.

EASE OF

INTEGRATION

Operates on the data your digital controls already have, simplifying the integration process.

iPID combines the best of both world:

Engineering and AI Models

In the rapidly evolving world of industrial maintenance, the key to staying ahead lies in embracing innovation.

ENGINEERING-BASED MODELS

Precision for Well-understood Machine Parts and Components:

+ High transparency and effectiveness, even with scarce data

+ Excels in situations where historical data on component failures is limited

Challenges:

— Requires extensive experimentation

— Demands intensive labor for development

— Only feasible for small machine parts or components: Bearings, gears, etc.

DATA-DRIVEN MODELS

Cutting-edge AI at Your Service:

+ Based on processing vast amounts of data to forecast maintenance needs.

Challenges:

— No proof of accuracy due to their “black-box” nature

iPID combines the best of both world:

Engineering and AI Models

In the rapidly evolving world of industrial maintenance, the key to staying ahead lies in embracing innovation

| ENGINEERING-BASED MODELS | DATA-DRIVEN MODELS |

|---|---|

|

Precision for Well-understood Machine Parts and Components: + High transparency and effectiveness, even with scarce data + Excels in situations where historical data on component failures is limited Challenges: — Requires extensive experimentation — Demands intensive labor for development — Only feasible for small machine parts or components: Bearings, gears, etc. |

Cutting-edge AI at Your Service: + Based on processing vast amounts of data to forecast maintenance needs. Challenges: — No proof of accuracy due to their "black-box" nature |

Want to know more?

Experience the future of machine health monitoring with iPID and ConnectedAI. Say goodbye to costly downtime and hello to seamless, efficient operations.

Want to know more?

Experience the future of machine health monitoring with iPID and ConnectedAI. Say goodbye to costly downtime and hello to seamless, efficient operations.

IEEE PAPER FEATURING THE SCIENTIFIC DISCOVERIES BEHIND iPID

CONFERENCE PRESENTATION TO SEE iPID IN ACTION AND UNDERSTAND IT'S PRACTICAL APPLICATIONS

Schedule a personal briefing with one of our data scientists

Please complete the form to download the resources and learn more about iPID and its revolutionary approach to predictive maintenance:

Please complete the form to download the resources and learn more about iPID and its revolutionary approach to predictive maintenance:

Together, we can transform your predictive maintenance strategy and elevate your industrial operations to new heights