ei3 has recently introduced two significant enhancements to its IoT application suite, giving manufacturers new ways to maintain competitiveness and improve their products and processes. These features are particularly relevant today because more manufacturers are seeking ways to boost productivity. For example, according to a recent National Manufacturing Survey by Marcum LLP, 60% of participants identified improving productivity as their top three priorities.

The first addition, “Scrap Tracking,” redefines machine quality assessment by tracking scrap material and helping to find the Q-Value — an important element for precise machine OEE calculation. The second addition is, “Run Rate OEE,” which allows customized target speeds for evaluation machine performance, further contributing to a more precise P-Value used in OEE calculations. This seamlessly empowers customers with comprehensive insights into their machines’ OEE, facilitating informed decisions and refined planning strategies for heightened operational efficiency.

Scrap Tracking – Simplified

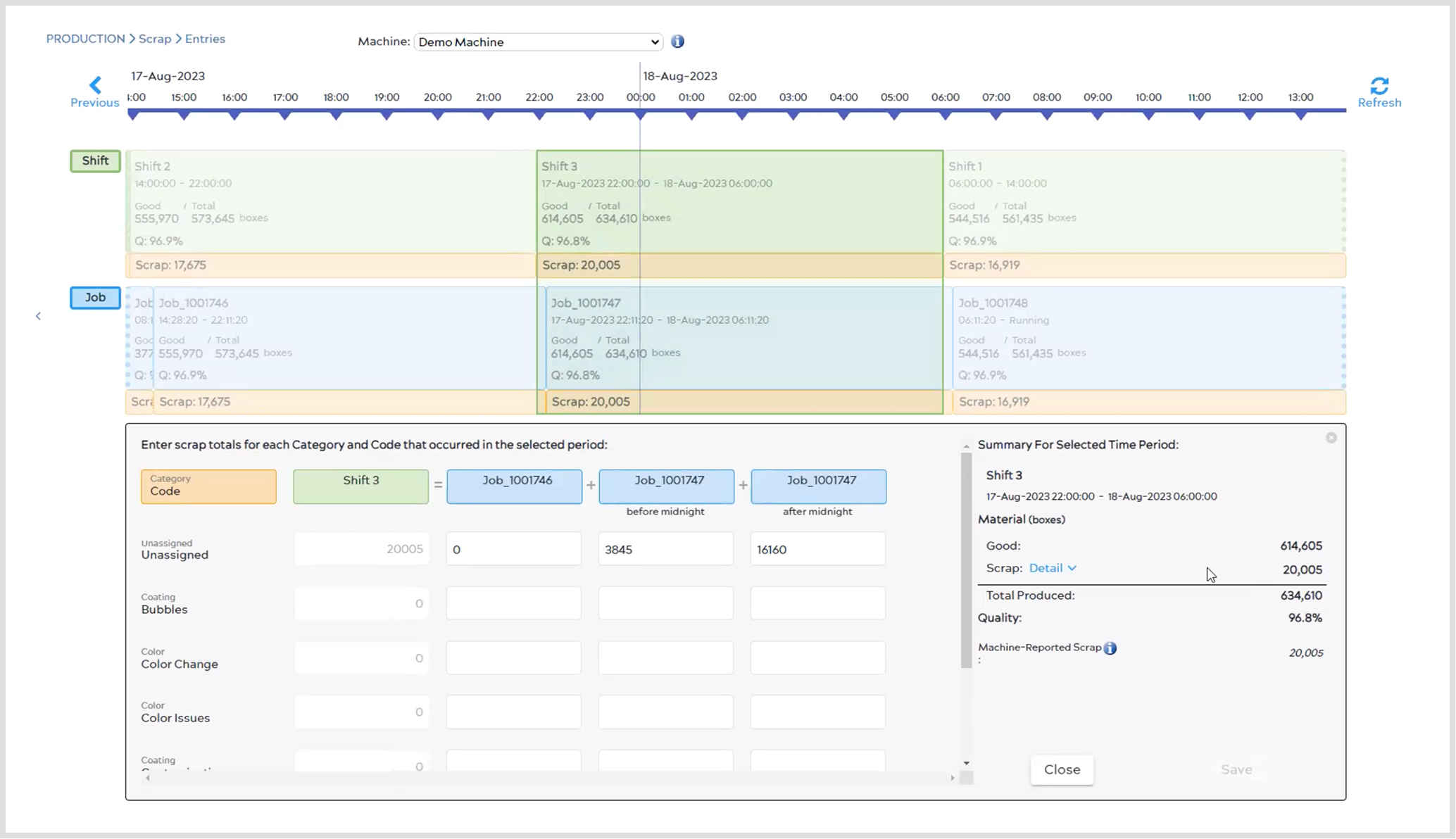

With ei3’s IoT application called PRODUCTION, users can track both machine-generated and manually logged scrap material, generating a Q-Value that reflects the ratio of good material produced to total material produced during a specific job. This offers a precise and user-friendly way to capture the data needed to compute a Q-Value and quantify defective material directly.

Users can navigate the Scrap Tracking easily because it has an easy-to-use and intuitive design. Each manufacturing site can create and customize categories and codes to meet their own business thereby setting up a detailed hierarchy for personalized quality tracking of products.

Fig 2. Inputting Scrap Data by “Job” or “Shift”

The built-in features, like the Pareto Analysis and scrap breakdown charts, provide quick ways to analyze the data to get results. The organized pareto charts are complete with categories and codes that can be easily exported for statistical analysis using PowerBI or Excel. This makes it easy to pinpoint areas of improvement and make informed decisions about production processes.

Furthermore, tracking scrap data to improve machine performance and minimize waste seamlessly aligns with company sustainability goals. This underscores its value in promoting environmentally conscious manufacturing practices.

Run Rate OEE – Precision on Your Terms

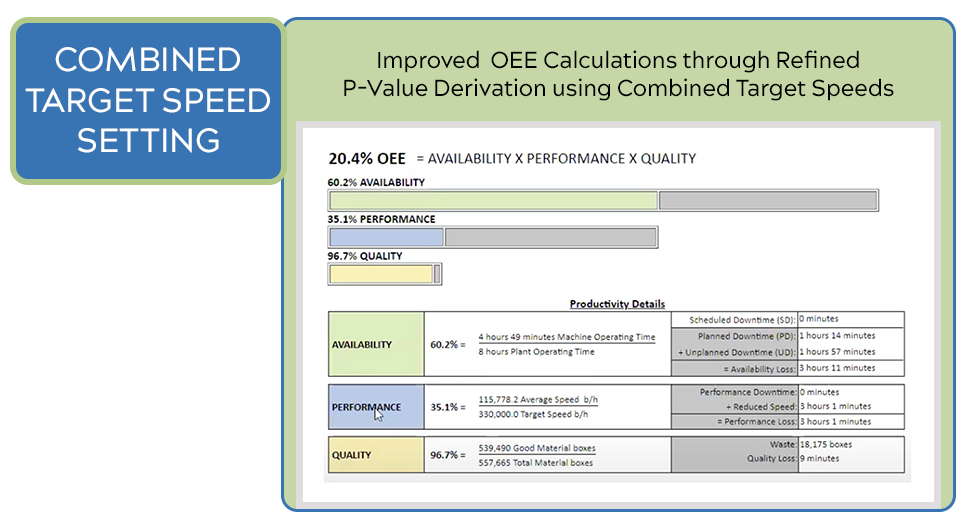

“Run Rate OEE” enables users to define target speeds for machine operations, enhancing P-Value derivation by eliminating the need for baseline comparisons across all machines.

In manufacturing processes, it’s common for a single machine to produce multiple types of products, each requiring specific operational parameters, such as different machine speeds. Prior to the implementation of Run Rate OEE, the standard approach involved using the machine’s maximum speed as the reference point for calculating OEE, resulting in the P-Value as the ratio of average machine speed per hour to maximum speed per hour. Run Rate OEE accounts for speed variations in a machine’s operation across different jobs, considering the intended target speed for each task. This yields a more accurate depiction of machine performance. This refined approach calculates the P-Value as the ratio of average machine speed per hour to the combined target speed per hour.

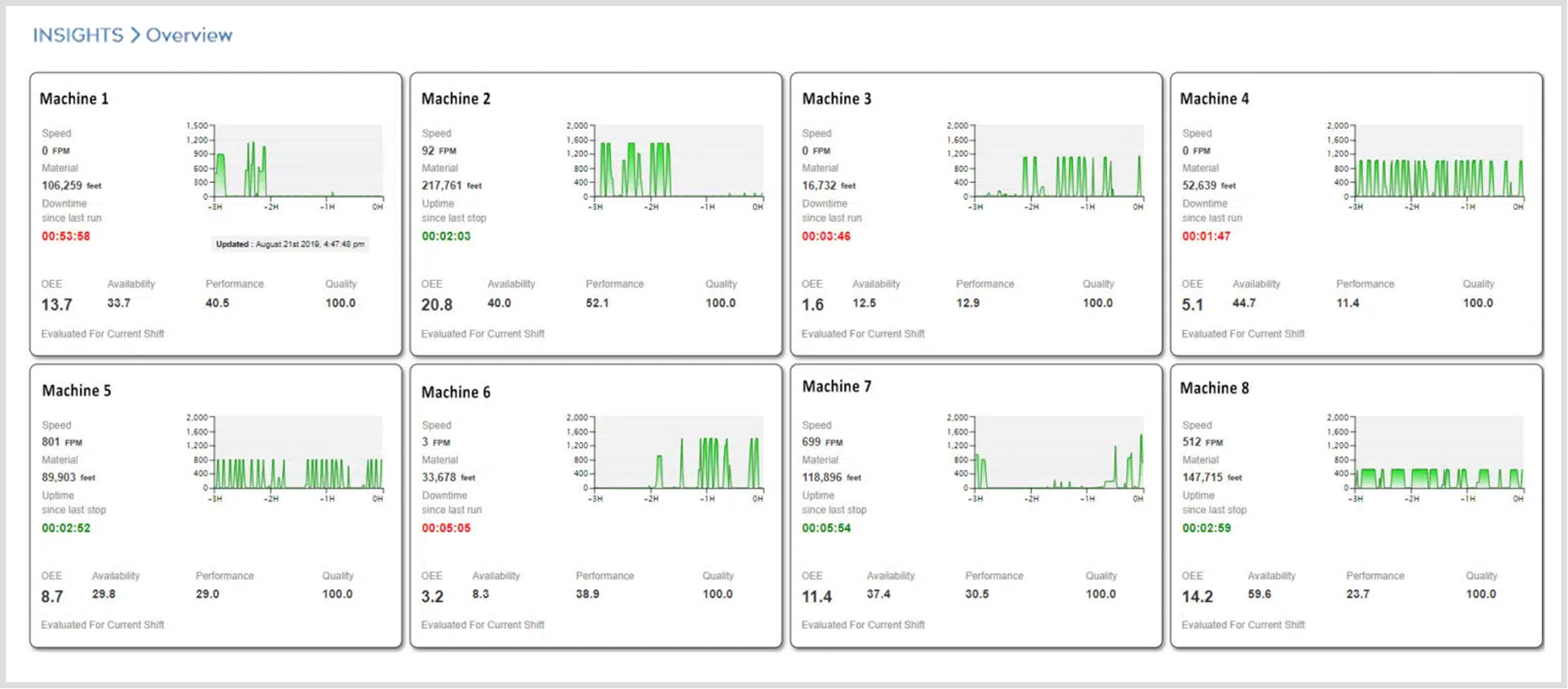

Run Rate OEE transforms the way data can be interpreted and analyzed. This data can be accessed through the ei3’s unique and powerful “INSIGHTS” where every user is given the ability to compose their own dashboards with no programming needed. This feature offers users options for productivity metrics, charts, and reports based on combined target speeds, significantly surpassing compared to the limits of maximum machine speed alone.

ei3’s Scrap Tracking and Run Rate OEE enrich OEE calculations, offering tailored, real-time insights. This allows machine owners to optimize machine settings for superior performance and improve overall manufacturing efficiency.

Fig 4. Combined Target Speeds Overview on INSIGHTS Dashboard

ei3’s Scrap Tracking and Run Rate OEE enrich OEE calculations, offering tailored, real-time insights. This allows machine owners to optimize machine settings for superior performance and improve overall manufacturing efficiency.