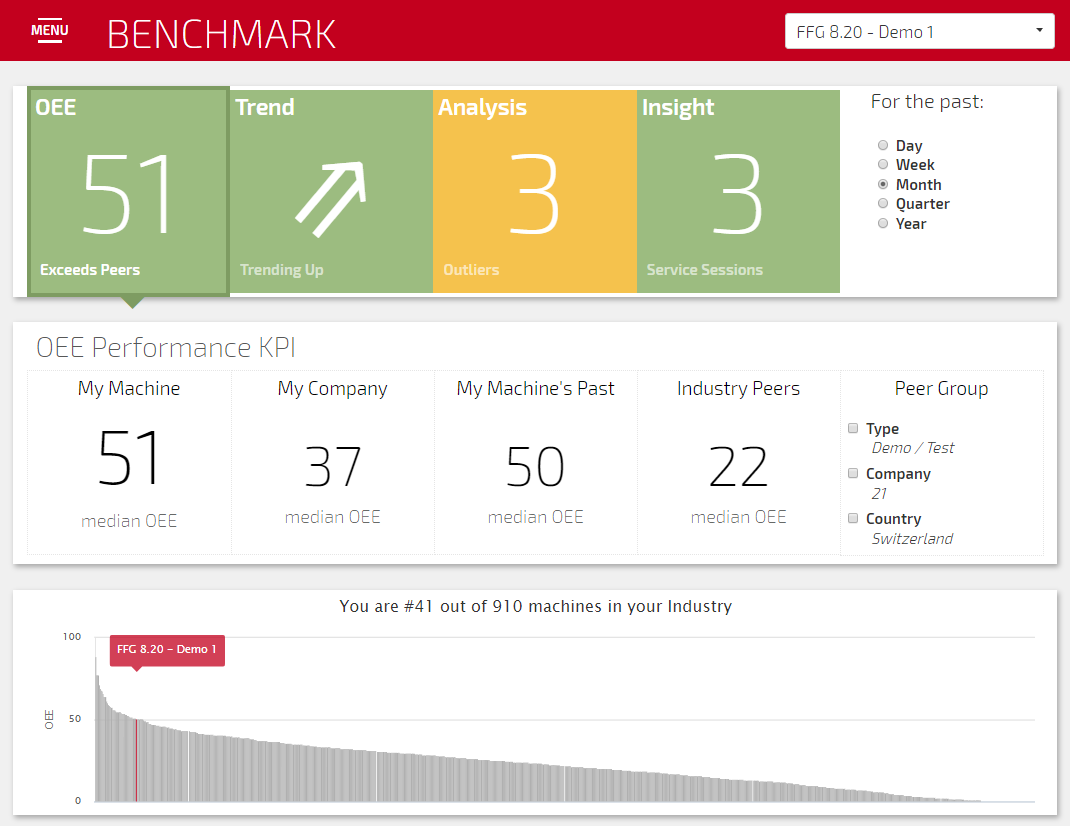

It’s hard to identify which machines need attention on a plant floor because there’s so much going on. If your plant is like most, you might have both new and old machines, they’re running simple and complex jobs, and each one has different specs and features. It may feel nearly impossible to tell which machines are running well and which ones need urgent service.

Enhance your production insights with ei3's PRODUCTION, offering a powerful tool to visualize your machine's performance and pinpoint both top performers and areas for improvement

ei3’s PRODUCTION application makes a real-time list that shows all your machines and how they are doing, by shift, job and day, simplifying OEE benchmarking. These numbers tell you the story of how each day is going for meeting production targets. Put web TVs on your shop floor and the machine operators will know how they are doing compared to targets. This is a perfect application for the IoT because complex analytics are done in a secure cloud, and a historical record is maintained.

Every machine connected to ei3 for production tracking is analyzed to determine real-time OEE. The OEE benchmark is used by lean manufacturing experts around the world to understand how well a machine produces. Best in class companies use OEE as their tool to improve operations. With ei3’s PRODCUTION you will find your leader and laggards, and by making the right improvements, you’ll boost production with the ‘hidden machine’. You can learn more about ei3’s OEE methods here.

Connect all your machines to ei3 PRODUCTION and display OEE with ei3’s Benchmarking tool. If you have more than a few machines connected you’re ready to use this powerful tool. Don’t worry if you have old machines without automation – there’s plenty of integration solutions available from ei3 to get what’s needed from any piece of equipment.