Watch – Bobst and American Packaging Corporation (APC) share insights on how they used ei3 to streamline their production, reduce waste, and increase asset utilisation. In doing so, they managed to make great products – better!

For packaging producers, converters and die-makers, achieving better-quality and increasing operational efficiency would involve significant capital expenditure, but thanks to the Internet of Things (IoT), it is low-cost and effective than ever before. When fully adopted, IIoT becomes part of a management culture that is driven by data facts and insights, creating maximum benefits for the organization.

Peter Drucker (arguable the inventor of modern business management) gets credit for the profound insight that you cannot improve what you cannot measure. Therefore, increasing business value is all about measuring things. And, the measurements and their analysis are not just backdrops to business decisions but become the core of them. IIoT takes the all important role of collecting, harvesting, and presenting that data.

Lee Blythe from APC, a long-time user of the ei3 solution which came with his Bobst machines, said it better than we ever could: “Every Monday morning our board gets the reports from ei3 and sets the agenda for the week.”

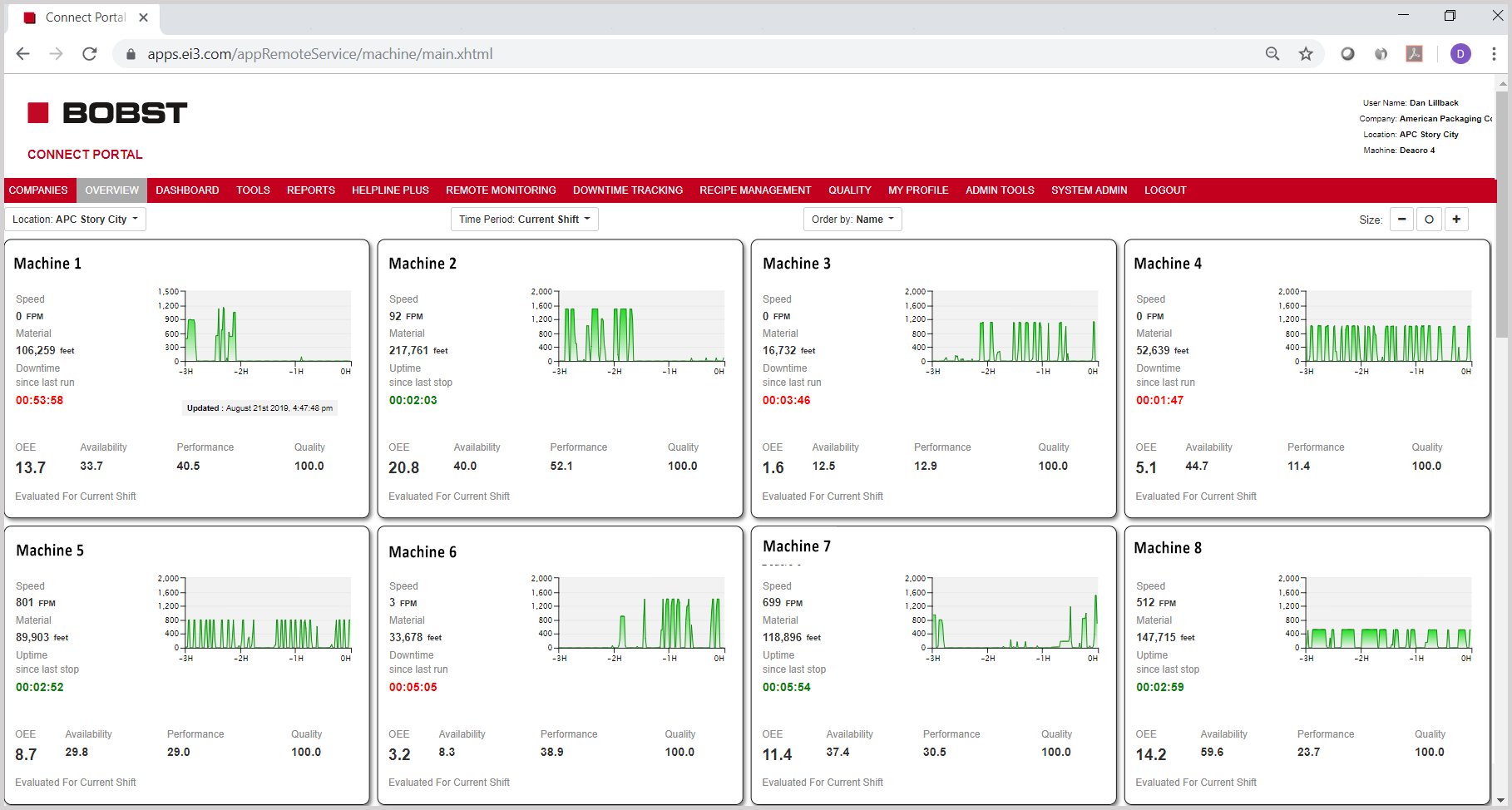

Fig 1. The image above showcases APC's Insights Overview dashboard, displaying key machine metrics such as machine speed, its OEE breakdown, material produced, and uptime

Lee talks about the transformation in their daily operations brought out by applying ei3’s cutting-edge technology.

- Ability to create Certificate of Analysis (CoA)s automatically based on real-time process data collected during manufacturing.

- Real-time lists that shows how all thier machines are doing, by shift, job and day to help find the leaders and laggards

- Tools to coordinate tests and capture Quality Assuarnce Results

- Alerting on deviations from key settings

- and more…

Our clients benefit from the value of IIoT in many ways; most commonly, increased asset utilization, reduced downtime, increased after-sales service revenue, and happier clients. The most impact we have is with clients that use ei3, not as a reporting tool but that have embedded the ei3 IIoT solution into their management culture. Because, as Peter Drucker discovered, managers need measurements.