The Challenge

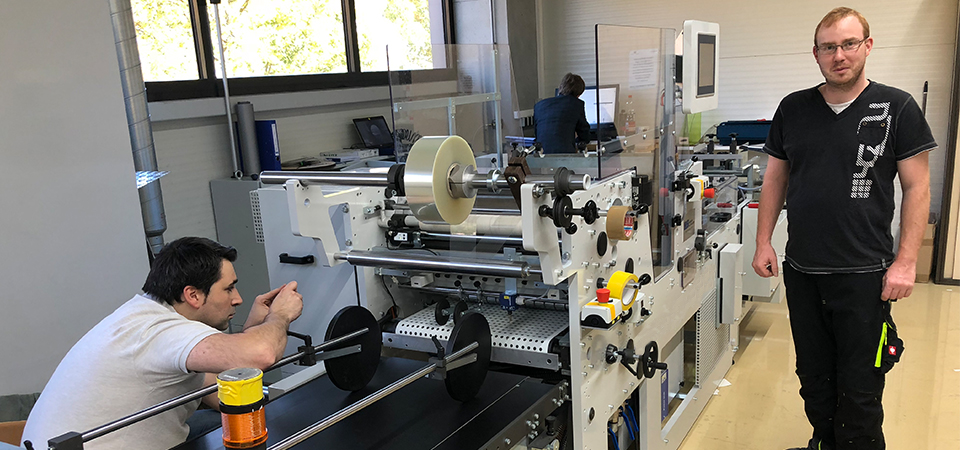

Our esteemed client, a prominent European OEM specializing in window patching machines, faced a significant hurdle in the form of downtime resulting from misalignments in the mechanical cutting mechanism. The precision of the blades on the rotating cylinder was critical for maintaining optimal cut quality. Unfortunately, any misalignment led to deteriorating cut quality and, inevitably, costly machine downtime. Traditional solutions involving alignment or replacement necessitated on-site visits from factory service technicians, prolonging the downtime and escalating expenses.

The Solution

In response to this challenge, ei3 introduced an innovative solution named Symphony, a broad-spectrum sensor designed to capture frequencies beyond the human ear’s range. Unlike human hearing, Symphony remains vigilant on the machine at all times, continuously listening for signals. Complemented by advanced AI-based machine learning algorithms developed by our skilled data science team, Symphony detects anomalies early in the operational phase of window patching machines, enabling predictive maintenance before any critical component fails.

Strategically positioned in close proximity to the cutting blade, ei3 Symphony identifies the deterioration of the cutting action well before it impacts the final result. This proactive approach allows for the creation of alerts long before the machine succumbs to downtime.

About The

Machine Maker

A leading manufacturer of top-tier tray forming and rotary window patching machines.

- Development, design, and production activities centralized in Germany

- Operations in 62 countries

Within three decades, this company has emerged as a leading force in the market, driven by an unwavering commitment to advancing the next generation of packaging solutions.

Results

70% Reduction in Unplanned Downtime

The implementation of our sensor solution has resulted in remarkable success for our client, with an estimated prevention rate of an impressive 70% of potential downtimes.

Cost Savings and Sustained Productivity

The transformative impact of our solution goes beyond downtime prevention, actively delivering substantial cost savings and sustained productivity, marking a significant achievement for our client.

Explore the potential of ei3's AI-driven Symphony sensor for window patching machines