One popular feature of ei3’s remote monitoring cloud is its ability to gather data from machine controllers – making it very easy to get machines online with extensive lists of parameters being monitored. This method leverages existing machine automation systems to save on hardware costs and installation time. But not every machine has the necessary automation equipment in place to provide data to the remote monitoring cloud. Certain machines might rely on discrete controls, or others may have automation systems that are not well documented or based on closed communications protocols.

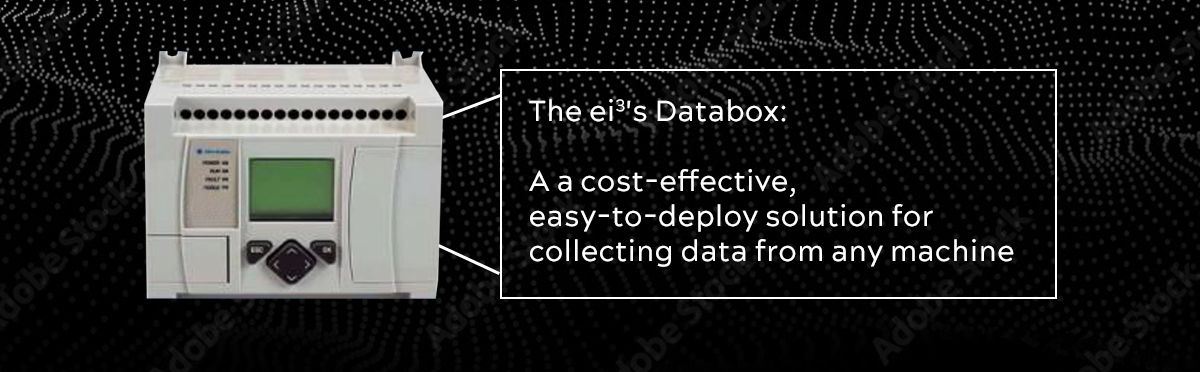

There is a practical solution available to collect data from any machine regardless of its existing electronics – its called the ei3 Databox. The Databox provides a cost effective, easy to deploy solution for acquiring data. Whether you are tracking machine production, quality or energy consumption, the Databox has the inputs needed. Wiring from key process points such as the unit production counter, or the machine speed sensor the Databox readily makes collects the values needed for ei3’s remote monitoring cloud. Networking connectivity is streamlined because the Databox has advanced networking features to integrates directly to ei3’s Amphion devices.

The Databox works by running ei3’s proprietary data gathering program running inside a Lenze 3200 Controller. This controller is globally available, highly reliable, and cost effective. The ei3 Databox program allows for users to configure and scale parameters for use within the remote monitoring cloud, by using either the fount panel LCD screen or web pages from secure web pages hosted in the cloud.

The Databox is the perfect choice for adding to a plant floor network to have a complete remote monitoring solution.

Features & benefits

- Works with the Amphion edge device and remote monitoring Cloud

- Web pages allowing users to configure monitored points

- Built in LCD screen for local calibration

- Advanced ei3 data collection program

- Standard with 10 digital, 2 Analog inputs

- Expand up to 16 analog points (Isolated)

- DIN Rail Mounting

- 24 VDC power supply