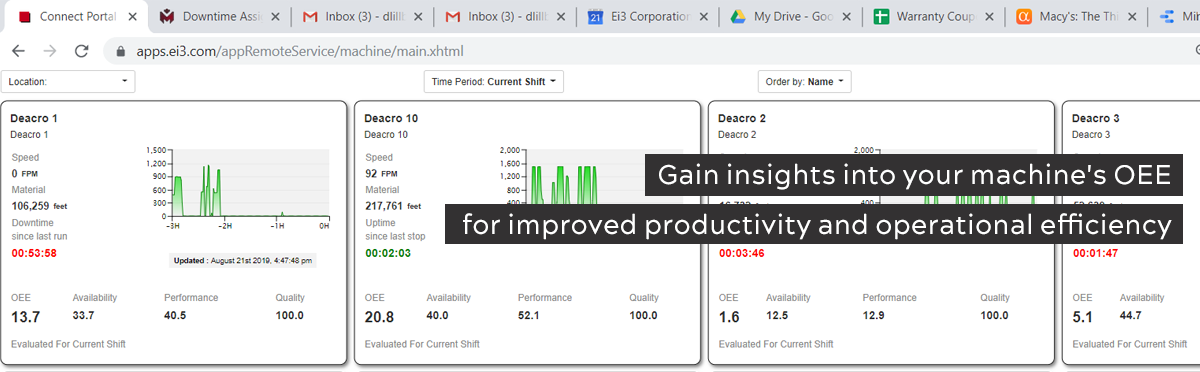

Organizations who are striving to achieve increased productivity in manufacturing have been using Operational Equipment Effectiveness (OEE) as a Key Performance Indicator (KPI). By calculating, displaying, and reporting OEE in real time, ei3’s online applications and productivity tools provide decision makers with the information they need to manage their operations. Through evaluating OEE and each of its three components, important insights are gained about how well the production environment is operating and what actions can be taken to improve it.

OEE provides a benchmark value that describes the overall performance of a single piece of equipment, or an entire factory. It is governed by the cumulative impact of three factors: the equipment’s availability (percent of scheduled production time available compared to all-time in the measured period), performance (percent of material produced compared to maximum capability of equipment to produce) and quality (percent of sellable material produced compared to all material produced).

Availability

Also known as uptime or uptime ratio, Availability is the time the machine spends above minimum production speed divided by the total time that the machine is available to be run. For a given time period, the Availability is computed as:

Availability = Time Spent above Min Production Speed / Total Time

Performance

Also known as speed ratio, Performance is the average machine speed for the selected time period divided by the maximum machine speed. The maximum machine speed is neither the fastest speed a particular product can be run on a machine nor the fastest speed a facility runs a machine. It is the maximum speed that the machine can run any product at any location. For a given time period, Performance is computed as:

Performance = Average Production Speed / Max Machine Speed

Quality

Also called material yield, Quality is the good material (material produced at or above the minimum production speed of the machine) produced during a selected time period divided by the total material (all material produced including startup and scrap) produced during the same time period.

Quality = Good Material / Total Material