Companies worldwide are making plans to leverage the industrial internet to enhance business operations. According to the recent “Internet of Things Business Index” report by the Economist Insights team, the manufacturing sector is leading the charge in adopting new internet technologies. Consequently, for machine-building companies, active participation in this revolution is more crucial than ever. However, the complexity of these technologies and business models can make entry into the realm of industrial internet seem daunting. The good news is that there are three practical steps machine builders can take right now to join this transformative movement.

Implementing remote service for your machines

Upon the introduction of broadband internet access, technicians began linking machines to the internet, facilitating remote access to controllers for diagnostic and troubleshooting purposes. However, heightened enterprise security concerns have led to reluctance among industrial plants to permit these initial connections. Today, advanced security solutions enable technicians to access systems while adhering to stringent enterprise IT requirements.

Experienced machine manufacturing companies routinely include remote service access in every machine they ship, recognizing its significant impact on reducing startup and warranty-related service visits. In fact, ei3’s customers have reported an impressive 80% reduction in these instances. Every connection is recorded, providing an audit trail of access. This remote service access information is a valuable tool to establish contracted service programs. Machine owners are ready to invest a reasonable fee for the machine builder’s technicians to access equipment, as they recognize that it reduces downtime and enhances productivity.

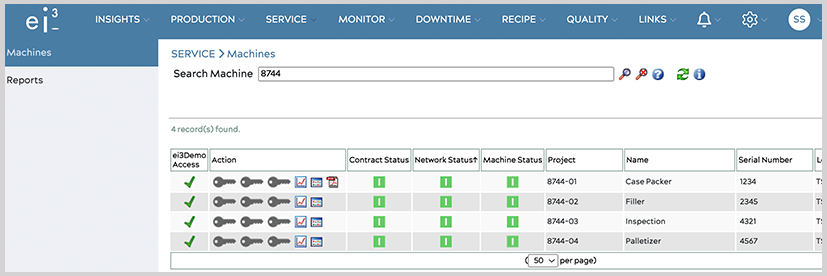

ei3’s SERVICE application, for example, provides a valuable solution for machine builders seeking to remotely diagnose and troubleshoot operational issues. Our unique “Zero Trust Remote Access (ZTRA) approach encompasses robust security measures, including meticulous vetting, rigorous machine validation and authorization, ensuring limited access to relevant assets, and a comprehensive documentation of remote connection activities.

Fig 1. ei3's SERVICE Application provides remote, real-time troubleshooting capabilities, allowing proactive resolution of downtime events and streamlining of production processes.

Employing a remote monitoring solution

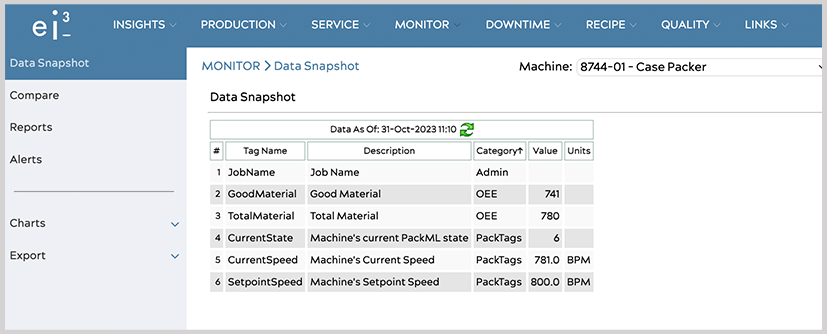

Machine owners recognize machine builders as trusted providers of remote monitoring services, creating an opportunity for branded solutions. However, successful remote monitoring goes beyond data; it involves creating algorithms to generate actionable insights.

For example, with ei3’s monitoring services, users can:

- Analyze machine performance data to proactively predict failures and send timely alerts

- Identify root causes of downtime and create reports to showcase trends

- Monitor production units to calculate Key Performance Indicators (KPIs) like OEE

- Track consumable usage to facilitate automated replenishment business models

Offering remote monitoring services allows machine builders to establish enduring, mutually beneficial relationships with equipment owners.

Fig 2. ei3 MONITOR facilitates real-time access to machine data points and allows for the setup of instant alerts in the event of parameter deviations

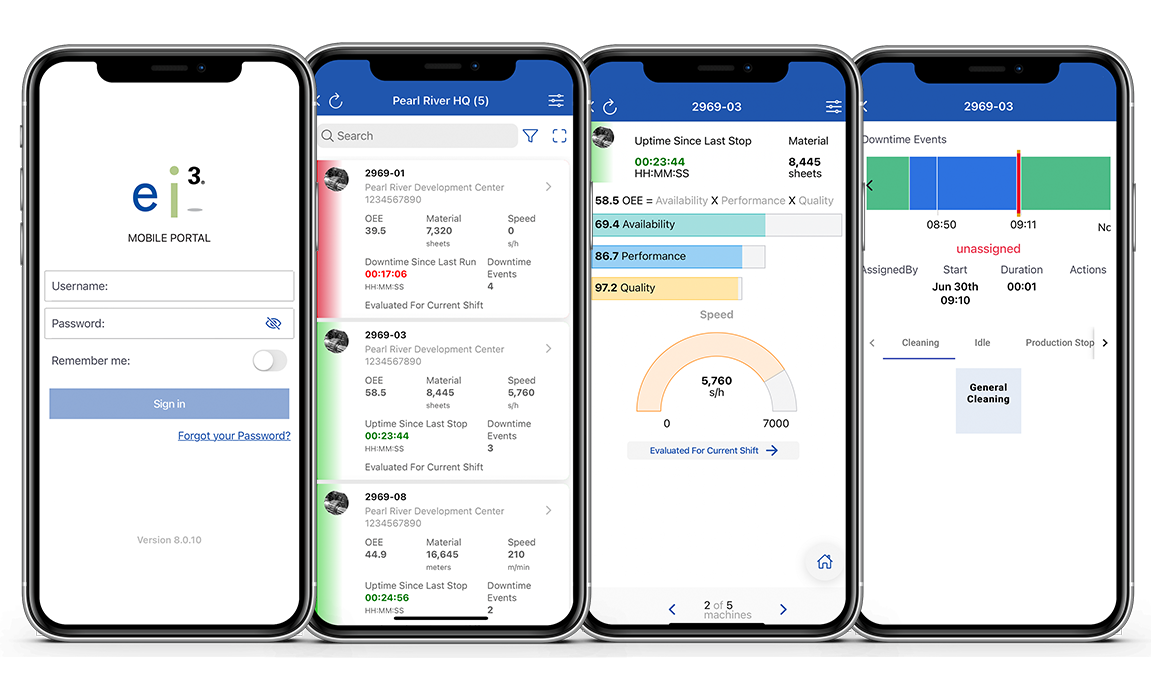

Utilizing mobile apps

Smartphones and tablets have transformed the way people work. Having data merely on web pages is no longer sufficient; it must be accessible on mobile devices, and placing critical operational information into the hands of those who are responsible for machines yields significant business value. wi3’s mobile applications provide real-time insights into machine metrics, encompassing OOE, quality, downtime, and more, facilitating easy access to industrial internet services.

Fig. ei3's mobile applications offer comprehensive insights into machine productivity.

Easily track OEE, downtime, uptime, and other key metrics from anywhere.

An efficient and low-risk approach to implement IoT services is through partnering with experienced and well-versed firms that deliver these solutions. This allows you to label the solution under your brand and have it hosted through a flexible subscription model known as Software-as-a-Service (SaaS). With this approach, companies can provide advanced industrial internet Services while focusing resources on their core strengths.

Contact us to explore ei3’s white-label solutions that enhance business efficiency and productivity.