Connect

Deploy secure connectivity with ei3’s edge technology

Transform your manufacturing operations with secure, intelligent IIoT solutions that turn machine data into measurable results.

A CPS Protection Platform that enables premium service, and control over industrial assets. Drive new capabilities with no-code applications that deliver immediate value.

Transform your production intelligence with our proven methodology that has guided leading manufacturers from basic connectivity to predictive excellence

Deploy secure connectivity with ei3’s edge technology

Implement IIoT applications to drive operational excellence

Expand capabilities across your enterprise with proven results

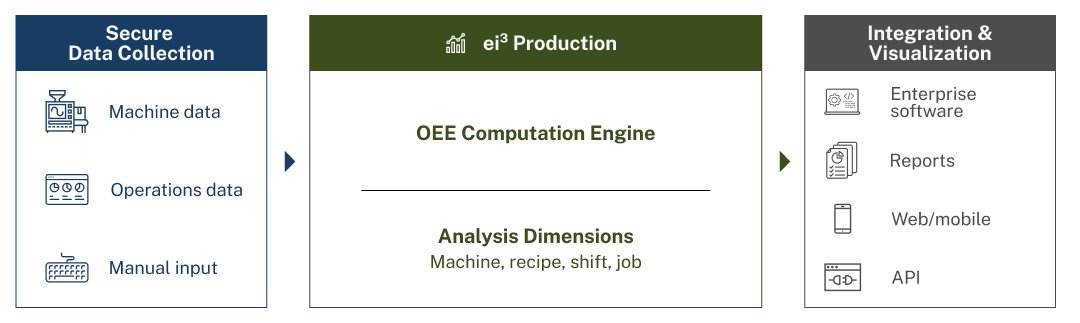

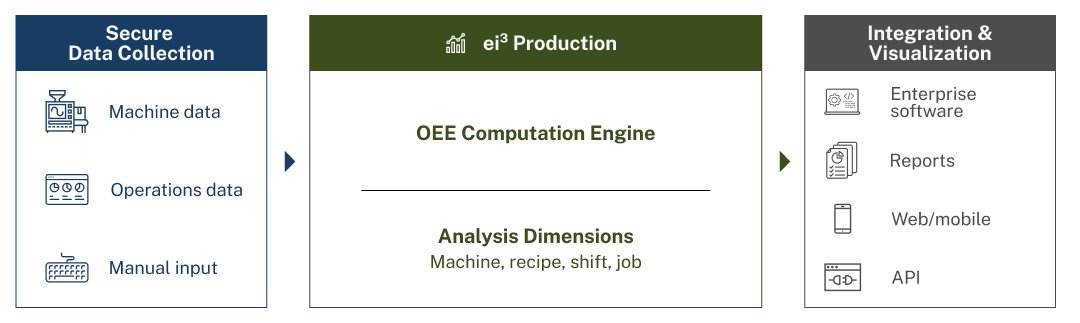

Drive measurable improvements in manufacturing efficiency through comprehensive production monitoring and analysis. Turn real-time machine data into actionable insights that optimize OEE, reduce waste, and improve quality across your operations.

Track OEE, availability, performance, and quality metrics with automated data collection and customizable dashboards.

Eliminate manual reporting with direct machine connectivity supporting 35+ industrial protocols.

Transform raw data into actionable insights through advanced analytics and AI-powered optimization.

Generate detailed reports automatically for shifts, jobs, machines, or entire facilities.

Track and optimize production performance with comprehensive tools that help you meet targets.

Transform production data into actionable insights with customizable analytics and reporting.

For Plant Managers:

For OPERATIONS Teams:

FOR QUALITY TEAMS:

Connect and protect your machine data with industry-leading standards

Seamlessly connect machine data with your existing business systems through our secure API gateway and extensive integration capabilities.

Built on ei3's CPS Protection Platform, ensuring

enterprise-grade security and complete data protection

across your operations.

Real-world implementation guides and case studies from industry leaders

Explore other components of the ei3 platform that make digital service transformation possible

Our team is ready to show you how smart technology can help. Whether you're exploring solutions or need support, we're here.